COLO-660 Electrostatic Powder Manual Coating Equipment,isdesigned exclusively for electrostatic coating with powder.

Typical characteristics:

1,Control unithas one-touch intelligent operation button good forflat parts, complicated parts and recoat parts.Easy to operate.

2,suitable for the coating of every workpiece. simple, flatworkpieces;workpieces with complicated shapes;the over-coating of workpieceswhich are already coated.

3,Pulse coating system

1). Save powder by 20% compare to Electrostatic Coating ,for theaverage thickness of our products is 60 μm compare to 70 μm of the latter.

2). Can coat the objects' deepest corner by charging the powdercontinuously with low current and high voltage.

3). Can reduce orange peel effect significantly compare to commonElectrostatic Coating machine .

Configuration:

A control unit power supply cable

- A air filter

- A air pressure regulator

- A fluidized powder hopper

- A plug-in injector

- An manual powder gun with gun cable, powder

hose, rinsing air hose and standard nozzle set.

- Pneumatic hoses for conveying air (red), supplementary

air (black) and fluidizing air (black)

powder hose

Ground wire

Data:

A) Control unit

Input voltage: 110V-220V

Frequency: 50-60Hz

Input powder: 50W

Pneumatic control voltage: 24V DC

B) Compressed air data:

Max. Input air pressure: 10bar/145psi

Min input air pressure: 6bar/87psi

Max water vapour content: 1.3g/nm

C) Powder Spray Gun

Powder yield: 600g/min

Gun powder: 550G

connection cable: 5m

Packing Dimensions

Model No. COLO-660

Length:69cm

Width:52cm

Height:56cm

Weight:37 kgs.

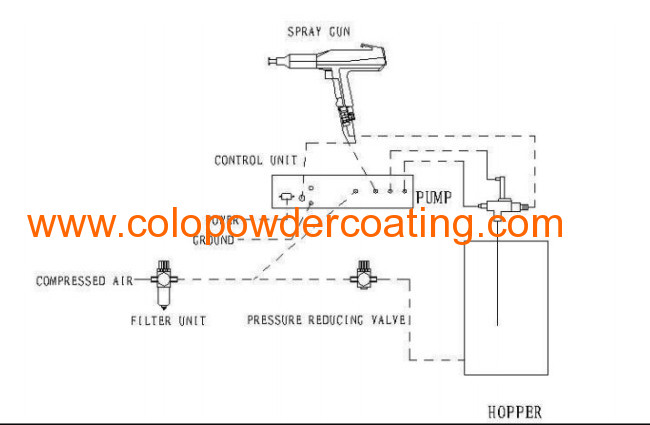

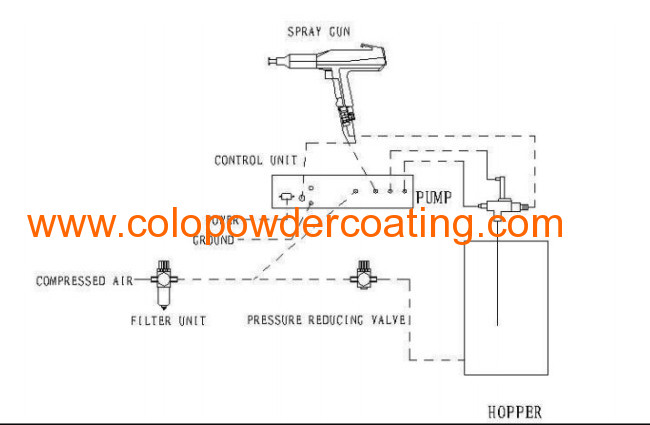

the powder gun through the powder hose . The powder iselectrostatically

charged at the nozzle of the gun. In addition, an electrostaticfield is

created between the gun nozzle and the grounded object. Thecharged

powder spray remains adhered to the surface of the object.

The powder is fluidized by air forced through a porous plastic platefrom

below. The powder acquires, thereby, fluid-like characteristics.

The conveying air, supplementary air, and rinsing air are set on thecontrol

Unit

The process of the coating is like this: The powder is fluidized inthe powder hopper. The injectors transport the powder through the hoses to theguns. The guns spray a powder/air mixture onto the workpieces

COLO Powder Coating Systems is a top supplier of powder coatingsystems and powder coating equipment including manual powder coating equipment,automatic equipment, spray booths,ovens and spare parts for itw gema, wagner,nodrson, kci famous brand in China.

China Powder coating gun, China powder coating machine, China powdercoating system, China

powder coating equipment, powder coating controlunit

You could buy the following equipments together:

booth:

Electrostatic powder spraying booth

1,Full automaticcontrol

2,Small area occupation

3,Low energy consumption

4,size iscustomize

5,Pulse valves and solenoids

6,Primary filter module:cartridge type

include fans, motors, nut and bolt fasteners, filters,detailed drawings and instructions, all included in one singleshipment.

powder spray booth is an economical solution for basicpowder coating operations requiring reclaim capability in continuous productionsituations.

For job shops, first-time powder coatersand to suppliment large in-house powder coating operations,this powder spray booths offer a variety of configurationoptions.

Booths size could Custom designed,Manual and automaticspray stations are also available.Other features include:

Durable, long-life powder-coated steel structure withhigh-quality galvanized canopy and floor

Low-profile booth base eliminates operatorplatforms

Requires only quick, easy conncet electrical and pneumaticsto start production .

Fan motor is 1.5KW-5.5KW.

During operation overspray powder accumulates on thecartridge filters. As the cartridge filters load, airflow decreases and thenegative pressure rises within the air handler. A timer activates a system ofair purging valves that clear the cartridge filters of the accumulated powder toensure maximum flitter life.

OVEN:

device configuration and description

1. Oven single-head double-leafdoor)

ID Size: 2000 × W 2000 × high 2000 (mm)

furnace wall materials:t1.0mm hot plate,

furnace wall materials: t1.0mm Valencia pressureplate,

insulation thickness: 100mm mineral wool insulation.

Railcar,angle iron welded together with a 4 #track angle.

Fan power 2.2KW.

2 return air system

A) Use the bottomdelivery, top recycleback to thecirculation, balance the hot air.

2) baffle wind deflector, floor punching,to ensure temperature uniformity.

3) circulation fan power: 2.2KW 1 units

3. Heating system heating power: 30KW

Heating system consists ofelectric heating with heat sink tubes, circulating fans, automatic temperaturecontrol probe and other components, electric heating pipe in the heating chamberby the heat after power cycling the fan directly to the bake house, by thecirculation fan continuously circulating, so that the internal oven temperaturerising to the setting temperature distribution uniform.

Automatic control anddigital temperature bake adjust the temperature. Combustion exhaust gas throughthe exhaust tube excluded.

When the temperature limit is reached, heat setoff automatically. Temperature limit automatically. Circulating fan usedinsulation qualities, plus the long axis of the treatment of low to effectivelyprotect the motor. automatic electrical control box both use Chinese famousbrand

factory: