all-new user-friendly CL-131

powder coating equipment helps you achieve highest productivity at the

best powder coating finishing

manual

coating equipment

Electrical data

Nominal input voltage 230-240 VAC

(110-120 VAC)

Frequency 50/60 Hz

Input value 150 VA

Nominal output voltage (to the gun) max. 12 V

Nominal output current (to the gun) max. 1 A

Protection type IP 54

Temperature range 0 to 40°C

(+32 °F to +104 °F)

Approval

Pneumatical data

Compressed air main connection G1/4'' - internal thread

Max. input pressure 10 bar

Min. input pressure 6 bar

Max. water vapor content of the compressed

air 1,3 g/m³

Max. oil vapor content of the compressed air 0,1 mg/m³

Max. compressed air consumption 11 m³/h

Connectable guns

COLO-06 OR COLO-03 manual spray gun

Manual Fluidizer Unit

Ideal for flexibility and economy for medium to large production runs

Using a standard round feed hopper, this unit provides excellent fluidization properties

for the majority of powder applications.

Features:

• User accessible, cart-mounted regulator for controlling hopper fluidization pressure

• Two pump ports on hopper give the user flexibility to use one or two guns on each

unit.

• Powder coated hopper body and lid, to insulate powder from metal and speed-up the

cleaning process

• Quick release clamp allowing easy breakdown for fast clean-up and color change

• Optional powered vent assist

• Large rear wheels on cart for easy maneuvering

Robust, easy-to-use gun and controller offer proven performance, exceptional versatility and high transfer efficiency in everyday coating applications.

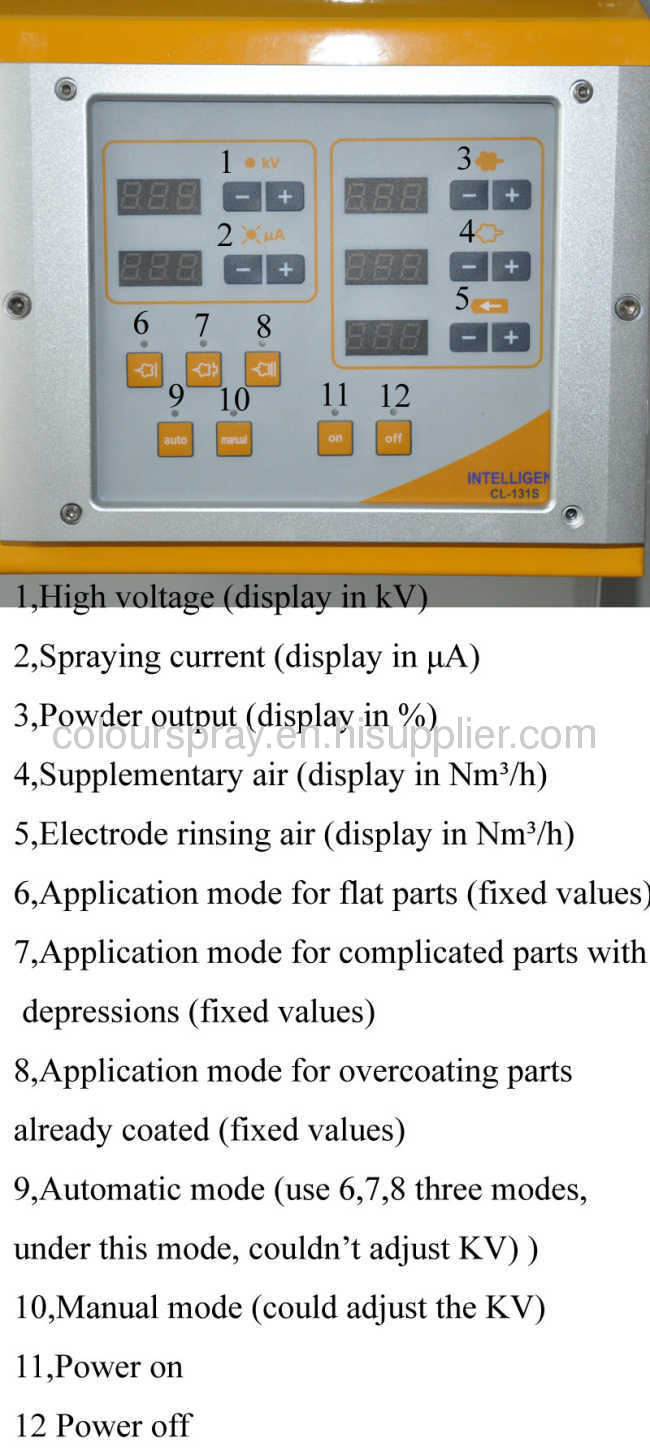

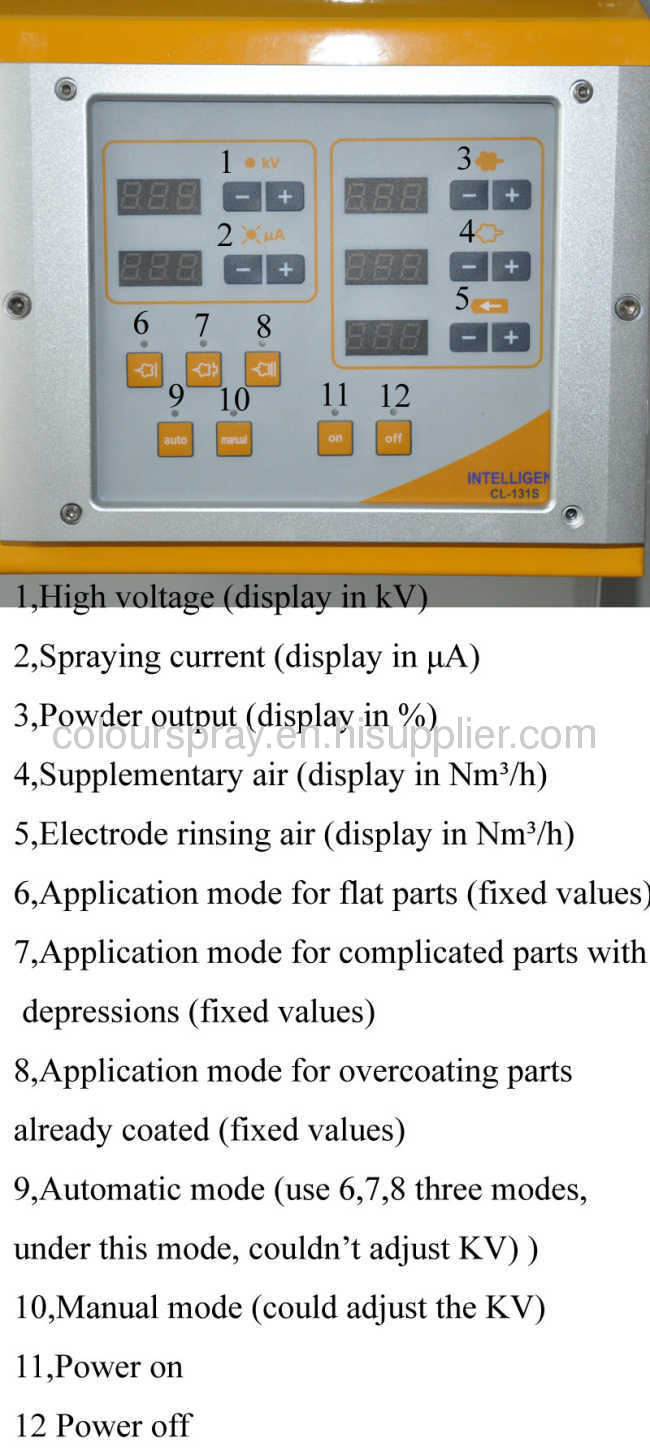

control unit

control unit

The DVC technology ensures a precise and constant powder

delivery and this results in a more uniform distribution and lay down of

powder

Electrostatic Spray Guns

Electrostatic Spray Guns Save powder

Save powder

The integrated 100 kV cascade delivers the highest transfer efficiency. This

means more powder on the work piece, less powder in the reclaim system!

Powder spray gun --colo-06 type also avaible with small powder cup

Fatigue-free operation

The manual gun is perfectly balanced and weighs

just 520 grams. You can work for longer,

- Quick-release powder hose connector for

easier maintenance and cleaning

- Compatible with metallic powders

- Reduced maintenance costs thanks to the

wear resistant design

electrically conductive carbon strip powder hose

Ideal for large powder quantities

- Compatible with all powder types

- 50-litre powder container

with fluidization

- Easy cleaning of the container

A. Hopper

1.Remove fluidizing AIR LINE

2.Remove injector

3.take our suction pipe

4.wipe the electric line , AIR HOSE .and powder hose cleanly with cloth

5.wipe the suction pipe clean

6.empty the remaining powder from hopper

7.clean the hopper s inner wall ,especially the bottom part , with vacuum cleaner

8.wipe the hoppers inner surface with clean cloth

9.replace the hopper to the original postion

CAUTION: the hopper must not be filled with powder unit work begins , Above all , the hopper s inner surface must not be cleaned with thinner or water

High Quality

powder injector

From relatively simple manual systems to sophisticated, programmable colo powder coating application technology improves efficiency, flexibility and productivity for manufacturers worldwide.

From relatively simple manual systems to sophisticated, programmable colo powder coating application technology improves efficiency, flexibility and productivity for manufacturers worldwide.

WARNING

--INSTALLATION

→Propery ground all equipment in the spray area to an earth ground and maintain this ground

→Remove all containers of volatiles from the spray area

→Establish and maintain a grounded area for the spray operator

→The gun of x series must be connect to x control unit

→OPERATION

→The operator should hold the gun in his bare hand

→If gloves are worm ,the palm should be out to assure skin to metal contact

→The operator should wear shoes with conductive shoes e.g leather

Rubber shoes are not conductive .

→Ground the tip of the gun before cleaning or changing nozzles.

→When the gun is not in use , it should be hung so that the nozzle is within four inches of a grounded conductor

→The operator should wear a filter-type respiator anytime he is exposed to dusty conditions

→High pressure powder many cause injury ,Keep the rear switch "off" position in no –use condiction

→MAINTENANCE

→Make a periodic confirmation of grounding to earh of all equipment in the spray area .

→Exercise good housekeeping practices , do not allow dirt or powder to accumulate on the feeder /powder unit , cable or gun.

→Keep the cabinet door

PERSONNEL

→Use saop and water to remove powder from the skin washing with solvents can cause reactions resulting in allergies and disourders.

→Wash hands before eating and smoking.

→Do not use compressed air to blow poder off the hands and clothing.

This practice may result in damage to the ear drums or eyes.

2. INSTALLATION

→Connects the control units MAIN AIR to MAIN AIR(REGULATOR) output unit with air hose

→Connects the control unit DOSING AIR to INJECTOR with air hose

→Connects the FLUIDIZING AIR (REGULATOR )output unit to HOPPER with air hose

→Connects the control unit AUXILIARY AIR to GUN with air hose

→Connects the POWDER HOSE to INJECTOR

→Connects the GUN CABLE to CONTROL UNIT with air hose

→Connects ground connection cable from ground nut to the booth and trolly

→Connect main powder cable

Workpieces type | Output voltage | 1ST air | 2sec air | Painting distance |

Big size new | 80-100kv | 4-6kg/cm2 | 2-3kg/cm2 | 15-20cm |

Corner,sides | 40-60kv | 2-3kg/cm2 | 0.5-1 kg/cm2 | 10-15cm |

repaint | 20-30kv | 2-3kg/cm2 | 0.5-1kg/cm2 | 15-20cm |

TROUBLES

Problem | Cause | Measure |

High –voltage display does not operated even after powder is on and trigger is pulled | . Electric faulty-The electric line coming into CONTROL UNIT is not property connected . Faulty fuse and bad equipemnt on the part of external power source . .Faulty lamp. .Faulty printed circuit board(PCB) .Faulty line in GUN .Faulty in high-voltage generation part .Faulty trigger switch | . connect the power Replace Preplace Preplace Preplace Preplace Preplace Preplace |

The powder would not be fluidized | .The fluidzing air hose is not connected or compressed air is not input . Faulty fluidizing plate . Faulty operation of pressure reduction valve | .Connect after checking .Replace .Replace |

The gauge hands of CONVERYING AIR and DOSING AIR do not move during operation | .operation mistake: The power switch is not pressed .The trigger is not pulled .Faulty SOLENOID valve .Faulty PCB | . Turn on the power switch .Check while pulling the trigger . Replace |