Powder coating is a dry finishing process,using finely ground particlesof pigment andresin that are generallyelectrostatically charged andsprayed ontoelectrically grounded parts.The charged powder particlesadhere to theparts and are held there untilmelted and fused into asmooth coating ina curing oven. Before coating,the parts to be coatedare firstpretreated similarly to conventionalliquid coated parts.Thepretreatment process is normally conducted inseries with thecoatingand curing operatios.

Thereis essentially two common ways ofapplyingpowder coating: byelectrostatic spray and by fluidized bedpowdercoating. There areseveral other processes that have beendeveloped, butthey are far lessused. These include flame spraying,spraying with aplasma gun, airlesshot spray, and coating byelectophoretic deposition.

To get an overview of the technology used in the powder coating industry click on the items below:

- pretreatment

- Electrostatic Spray

- curing

Pretreatment.

Phosphating,or conversion coating, istheapplication of an iron or zinc phosphatecoating to thesubstrate.Conversion coating can be a very critical partof thepretreatmentprocess, adding significantly to the performance ofthefinished coating.A phosphate coating converts the metal substrateto auniform, inertsurface, which improves bonding, minimizes thespread ofoxidation if thecoating is scratchedand improves the overallcorrosionresistance of thefinal part.

Aconversion coating can be iron,zinc,polycrystalline, chromate, ormanganese phosphate film. Theyaredeveloped on both ferrous (ironbased) and non-ferrous surfaces(zinc,aluminum, terne and manganese).Parts are subjected to an acidicbath anda chemical conversion forms acomplete film on the partsurface,changing the chemical and physicalnature of the metal surface.

Henkelhas introduced a big breakthrough insurfacetreatment: Bonderite NT –a new surface pretreatment whichisconsiderably more efficient, lesscomplicated and morecost-effectivethan conventional iron phosphating

Electrostatic Spray

Electrostaticspray

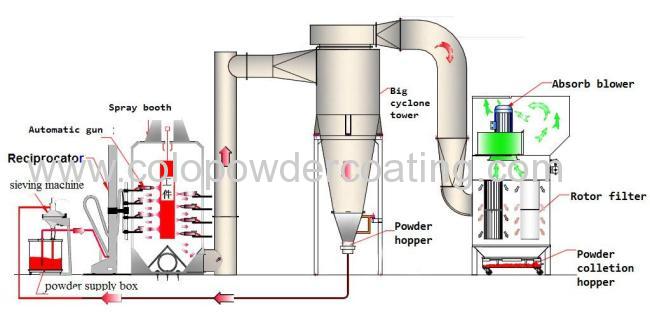

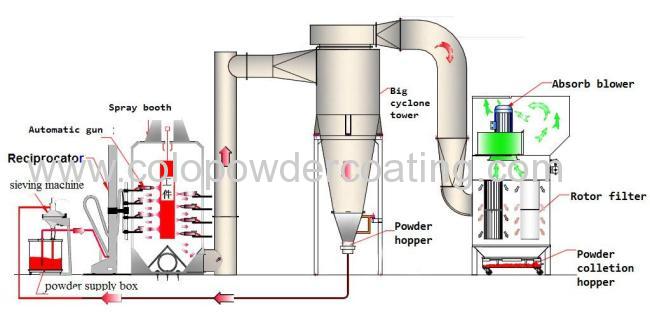

powder coating uses apowder-airmixture from a small fluidized bedin a powder feed hopper.Insomecases, the feed hoppers vibrate to helpprevent clogging orclumpingofpowders prior to entry into the transportlines. The powderissuppliedby a hose to the spray gun, which has acharged electrode inthenozzlefed by a high voltage dc power.

Electrostaticpowderspray guns direct theflow ofpowder; control the depositionrate; controlthe pattern size,shape, anddensity of the spray; andcharge the powderbeing sprayed .Thesprayguns can be manual(hand-held) or automatic, fixedor reciprocating,andmounted on one orboth sides of a conveyorized spraybooth.Electrostaticspray powdercoating operations use collectors toreclaimover-spray.This reclaimedpowder is then reused, addingsignificantly tothe powdercoating's high transfer efficiency.

Therearevarious gun designs that mainlydiffer inthe method ofapplyingelectrostatic charge to the powder. Insome cases,the powderiselectrostatically charged by friction. Theadvantage isthat thepowderis free to deposit in an even layer over theentiresurface of thepart,and deposition into recesses is improved.

Thefilm thickness is dependent on thepowderchemistry, preheat temperature,and dwell time. Film thicknessesof (40 -60 µm) in case of plain powder (80 – 100 µm) in case of texturecangenerally be applied on products.

Four work-positions(two reciprocator work position and two manual supplement spray position ), arced roof,V bottom,The main cabin made by powder coated plates,the V-bottom made by stainless steel

Lighting system:6 sets.The lights are be installed outside of the booth so that it is easy to repair and can't polluted by the powder.

Bottom has automatic blow system.This system blow the powder in the bottom automatically,so that the powder could be sucked in time by the recovery system.

Barker Jørgensen blower and ABB motor,low noise and long-time use.18.5KW Power, Air flow: 10000-12000m3/h

Advanced system to separate the air and powder,and recover the good powder by powder return system.

For the automatic line,one set of four-work positions booth just need install one set of Large cyclone and pulse recovery system

9 sets of 2 units-rotor system;Filter QTY: 18 ;Valve QTY:9

Curing

Whenathermosetpowder is exposed toelevatedtemperature, it begins tomelt,flows out,and then chemicallyreacts toform a higher molecularweightpolymer in anetwork-likestructure. Thiscure process, calledcrosslinking, requires acertaindegree oftemperature for a certainlength oftime in order to reachfullcure andestablish the full filmproperties forwhich the materialwasdesigned.Normally the powderscure at 200°C(390°F) in 10 minutes.Thecuringschedule could vary according tothemanufacturer'sspecifications.

The application of energy to the product to be cured can be accomplished by convection cure ovens or infrared cure ovens.

Application:

Application: