1,

Electrostatic powder coating plants

2,0-100KV adjustable

3,CE

4,used for powder coating line

5,automatic powder coating line

complete Aluminium Profile Powder Coating Line , powder coating plants, powder coating plants, powder coating system,coating machine,paintingmachine ,overhead conveyor system , spraying booth,conveyor systems andpretreatment system and so on.

Quick Detail:

Theentire aluminium profile powder coating line is including: pretreatmentsystem, dry -off oven ,

powder coating booth system,automatic powdercoating gun , manual powder coating machine, curing oven,control systemand conveyor system.

step 1) pre-treatment

To get a clean and protected surface of the work piece before coating, it is needed to prepare the surface of

the work pieces with the actually needed pre-treatment method.

twotype pretreatment ,1) tank immersion type, 2) vertical spraying systemmade of stainless steel. The tank immersion type is for semi-automationline, you can use cement tank or stainless tank. While vertical sprayingsystem is for full automation line. according to your productioncapacity to choice suitable one . Tank immersion type pretreatment iseconomical choice as well asvertical spraying system is of highefficient with easy cleaning.

tank immersion type pretreatment

tank immersion type pretreatment

vertical spraying system

vertical spraying system

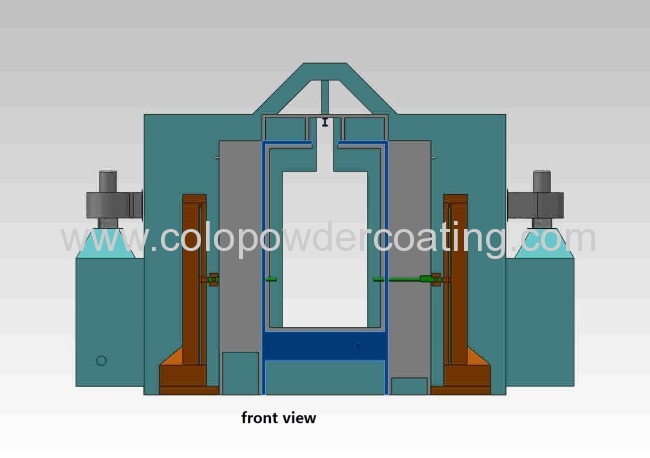

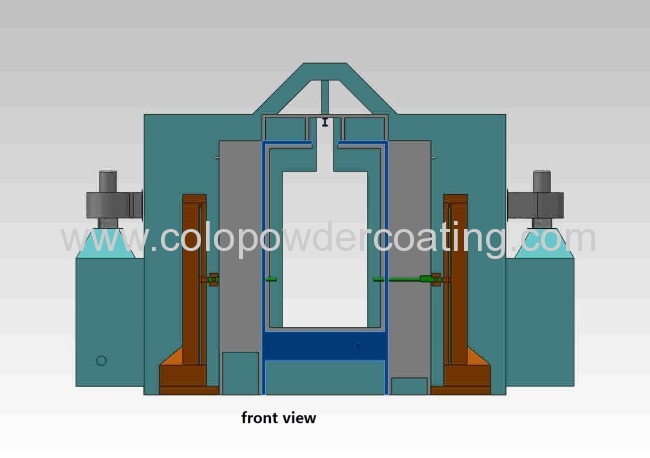

Powder booth:

Various range of industrial powder booths is based on a modular concept, which enables each booth to be

customized to suit any specific requirement. The size of the Manual & Automatic Booth is determined by the

size, the speed and the shape of the objects to be coated. The high efficiency cyclone collector recovers as

much as 98% plus of the powder exhausted from the booth. It has 2880 rpm motor with highly efficient impeller

given a rotary motion which creates a centrifugal force on particles. After filter Bag System for Non-Pollution

Area.

Exclusive Features:

Optimal system design to ensure powder containment while meeting industry safety standards

Maximum recovery efficiency

Multiple color capabilities

Easy cleaning

All filter media accessible and easily replaced

Minimal maintenance required

Versatile design to meet changing production requirements

Optimum use of plant floor space

Minimal plant air and energy requirements

Safe operational noise levels

according to your details request we have three type automatic powder spray booth for your choose

automatic spray booth with muti-cyclone

big cyclone spray booth recycles system

Curing oven avaiable heating sourceelectrical, gas or diesel fired. Whether batch type or conveyorized tunnel type. Designed and built specially for

Powder & Liquid curing purposes assuring you of low power consumption with uniform temperature throughout

the working space in the oven.

Melting & Curing constitutes a highly critical phase of the powder coating process. The curing schedules

recommended by the powder or liquid supplier must be strictly followed, if good adhesion & corrosion resistance

is to be achieved. While powder melts at approx.100°C, curing requires higher temperatures usually between

180°C to 200°C.If the curing is inadequate, the quality will be brittle and flake-off easily. If the powder coat is

exposed to harsh heat its colour may change.

Construction:

Welded or modular construction with high quality M.S Sheet

Hot air circulating blower for uniform heat

High quality insulation (Glass/mineral wool) to eliminate heat loss

Electrical,gas& diesel fired (heat exchanger)

Digital temperature controller with auto on/off or manual

Asbestos gasketing, flap sliding doors

Perfect locking arrangement and heat resistant paint(inside)

Powder Coating Confeyor Systems

according to the max weight of product can choose the different type of chain ,track ect

The process is as follow:

Feed your aluminium profiles on crane hanger for the preparation for chemical cleaning

washing stage

Passivisation stage

washing stage

Drying off oven to remove surface moisture

Manually transfer the pre-treated objects to powder coating line

Powder application with spray guns

Powder curing

Finished product discharging

1,Powder coating plant consists of pretreatment, powder coating, drying oven and curing oven, conveyor system and electric control system.

It will help user expand output, form mass production and reduce cost in order to make products' price more competitive.

1.Compective price

2.Energy saving

3.Output improve

4.Clean and economical