|

Hangzhou Color Powder coating Equipment co.,ltd

|

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

electrostatic painting line

I,Design basis(user supply)

1. product name: Electrical switchgears/Panels

2. material: Metal

3. product max size: 1200x2400x500mm

4. product max weight:70Kgs

5. Max output every day(8hours):

6. color:

7.coating area: surface

8. coating : manual powder coating

9. Drying tunnel heating: LPG heating

10. Compressed air: the users themselves, freeze-drying, moisture content <1.3g/m3 oil content <1PPM

11. Plant area:

12. Energy: (1) three-phase five-wire (380V). With a ground wire (2) Compressed air

II,Powder Coating Plant Components

1. Stainless Steel Spray Type Pre-Treatment Tunnel, 1 Set

2. Spray Type Degreasing System, 1 Set

3. Heating System for Degrease Zone (Gas) 1 Set

4. Spray Type Phosphate System, 1 Set

5. Heating System for Phosphate Zone (Gas) 1 Set

6. Spray Type Rinsing System, 2 Sets

7. Water Drying Tunnel 1 Set

8. Water Drying Tunnel Burner (Gas) and Heat Circulation System 1 Set

9. Powder Coating Curing Tunnel 1 Set

10. Curing Tunnel Burner (GAS) and Heat Circulation System 1 Sets

11. Spraying Booth 1 Set

12. Filters Recycle System 2Set

13. COLO-660 Manual Electrostatic Powder Coating Guns with Control 3Sets

14. Auto Electrostatic Spray Guns with Control 1Sets

15. COLO-2000D Reciprocators, 2 Sets

16. Suspension Type Conveyor Line with Drive 1 Set

17. Electronic Control System 1 Set

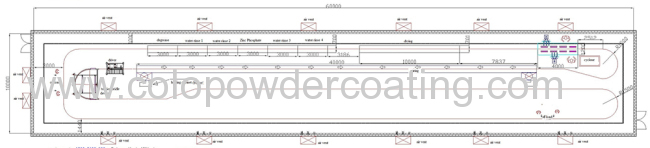

III.DRAWING:

Production Procedure:

Work Piece Loading→Spraying Type Degreasing(About 3minutes 50℃)→Spraying Type Rinsing(About 2minutes) →Spraying Type Phosphate (About 3minutes,50℃)→Spraying Type Rinsing(About 2minutes) →Water Drying (10 Minutes,110 ℃) → Automatic + Manual Powder Coating → Powder Curing (25minutes, 180~200℃) → Unloading

Equipments specification:

auto shower pre-treatment

Water Drying Tunnel and powder coating curing oven

Size: L10*W0.7*H2.2(m)

insulation board: thickness 100mm, Inner furnace plate material: thickness 0.8mm SPG plate

Outer furnace plate material: thickness 0.5mm color steel plate

Underframe: 10# square tube

Heating buner power: 100000 kcal/h ------1pc

Heating room: insulation plate same as oven body plate, 80-200℃,adjustable.

circulating fan: 5.5HP-----1pc

Powder coating curing oven size(outer) :L40 x W0.7x H2 (m)

1,Oven body plate: composite rockwool panel t 120mm

Inner furnace plate material: t0.8mm SPG plate

Outer furnace plate material: t0.5mm color steel plate

Underframe: 10# square tube

2,Air tube: t1.2mm galvanized plate

Gas heating system

Heating room: insulation plate same as oven body plate

Burner: 200000kcal/h, 2pcs

circulating fan: 5.5HP, 2pcs

3 ,Electric control: automatic constant temperature, digisplay control 180-200℃, adjustable.

Powder coating spray booth

1,Powder spray booth size(inner): L4xW1.2xH2.2(m)

2,Booth body room: galvanized plate t1.2mm

3,Underframe: 4# square tube

4,recycling filter: Ø325x660mm 10pcs, cyclone----9pcs

5,Recycling fan: 7.5kw 380v 1pc

6,Electric control unit: good quality brand products home and abroad

1,Powder coating machine—3set colo-660

1)intelligent control unit ,digital display for voltage,current

Imported Italy parts, good for recoating,complex workpieces,100kv adjusted powder coating gun with stainless powder hopper.

2)included:

Control unit –1pcs

Powder coating gun -1pcs

powder hopper ---1pcs (44LB)

Trolley—1pcs

Powder pump-1pcs

Oil filter-1pcs

Fluiding unit-1pcs

Power cable—1pcs

Groundly cable-1pcs

Air tubes—3pcs

3)electric technical

Input voltage:AC220V/50Hz +/-10%

input power:≤50W

Working voltage:DC24V

Voltage of gun:0—100KV(ADJUST)

Max curring:100UA

Automatic Reciprocator—2pcs colo-2000D

1)Frequency-adjustable reciprocator is specially designed for high quality powder coating, it can carry up to three spray guns.

Frequency: Japanese Mitsubishi

2)General information

Maximum available programs 80

Max stoke height 1.5m

Maximum speed 0.8m/s

Minimum speed 0.08m/s

acceleration 0.1m/s2

3)Electrical data

Nominal input voltage 170-264VAC single phase

Tolerance +10%/-10%

frequency 50/60hz

Fuse 10.0AT

Power consumption 2.5kw

Auto Spraying Guns Powder Coating System 1 Set

[Main Configuration]

1. Centralized Control Box | 1 set |

2. Internal Static Electricity Generated Guns--660A | 4Sets |

3. Air pipe and Powder Pipes and 12 V Control Cable | 4 pcs |

4. Powder Supplying/ storage unit--660 control unit | 4Sets |

5,sieving machine--660 gun | 1 sets |

[Main Parameters]

1,Spray Gun with auto cleaning function, internal high voltage template, input voltage 12V, output voltage 0 – 100KV adjustable |

2, Gun Spraying Rate:2~7kg/h |

3,Control Cable: 10000mm (Length), simple connector, one way control |

4,Control Box: Short-circuit protection |

5,sieving machine: Stainless steel screen Ф 360mm 50-100mm, Dimension: dia:1500px, height1500px, Powder pump: 4pcs |

overhead conveyor

No. | name | Specification |

1 | Suspension chain model: | QXG-235 |

2 | Pitch: | 200mm |

3 | Single point of hoisting: | ≤120Kg(including the spreader) |

4 | The total length of suspension chain: | 103m |

5 | The work piece using suspension point: | Double point hanging (condition: refer to layout) |

6 | Design speed: | 2m/min (free chain adjustable: 0.5~2.0m/min) |

7 | Adjust speed device: | Single drive + single tension |

8 | Installed power: | 2.2KW |

9 | Oiling device: | 1set(automatic oiling device) |

10 | flange | 35pcs, 1pcs/3000mm |

11 | spreader height(height that rail top to work piece ) | 800mm(refer to the layout)

|

12 | Horizontal rail bending and vertical curved rail | 16 manganese steel |

13 | Balance crane beam | 11pieces |

14 | The second hanging: | User supply |