|

Hangzhou Color Powder coating Equipment co.,ltd

|

| Price: | 10000.0~50000.0 USD |

| Payment Terms: | T/T,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

| View the Video: |

|

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

1. Design Principles:

1. Powder Coating Object:

a) Items: Aluminum, Steel, MAX SIZE:2500×72mm(L×dia),30 kgs/piece,

2. Powder Coating Method: Automatic Powder Coating + Manual;

3. Curing Oven: Electric infrared Type Heating,

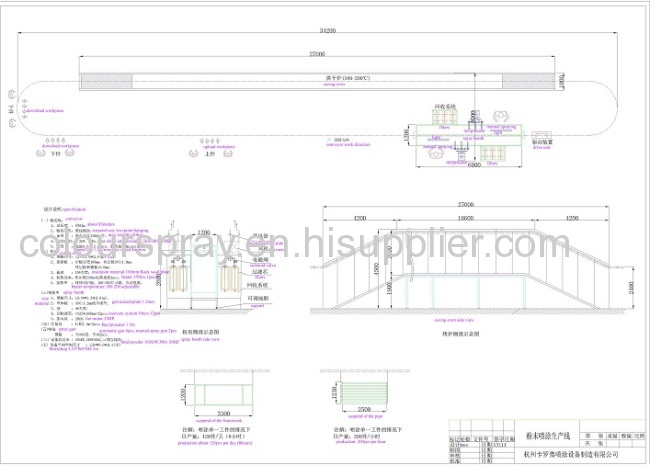

4. Workshop Area: 35000×6000×5300mm(L×W×H)

2. Production Procedure:

Work Piece Loading → Automatic + Manual Powder Coating → Powder Curing (20 minutes, 180~200℃) → Unloading

3. Powder Coating Conveyor Speed:

1. Conveyer Type: Suspension Conveyer Chain System

2. Production Line Working Speed: 1m/min (adjustable 0.5-4m/min),

(conveyor speed adjustable by inverter 1m/min);

3. Coating Curing Time: 18 minutes, Curing Tunnel total length 27 meters.

(Including 3.6meter entry and exit)

4. Powder Coating Plant Components (see supplied DWG)

1. Powder Coating Curing Tunnel 1 Set

2. Curing Tunnel Burner (electric) and Heat Circulation System 2 Sets

3. Spraying Booth 1 Set

4. Six Filters Recycle System 2Set

5. COLO-500-PGC1 Manual Electrostatic Powder Coating Guns with Control 2 Sets

6. Auto Electrostatic Spray Guns with Control 12Sets

7. COLO-2000D Reciprocators, 3 Sets

8. Suspension Type Conveyor Line with Drive 1 Set

Electronic Control System 1 Se

the photos before powder coating line loading in the container

painting the track before shipping

before shipping ,the last checking

automatic painting robot

part of convery line

powder coating line layout