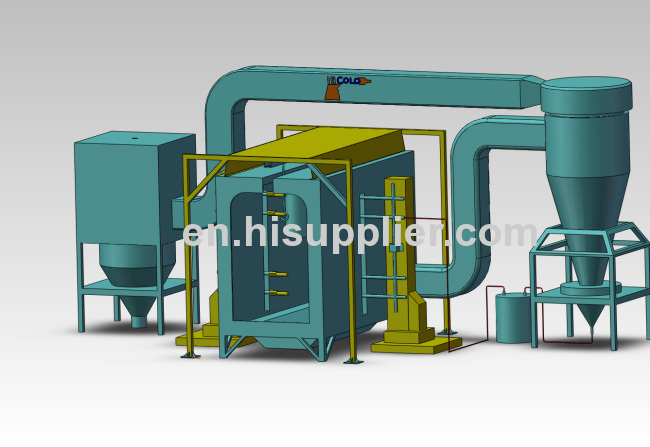

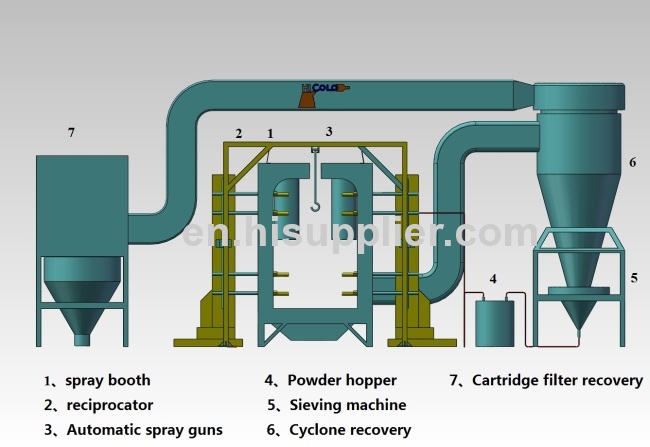

The powder booth is one of the most critical components of the product finishing process,thisMulti-level cyclone separator plus double grades recycling, to recycle more powder and eliminate powder leakage. Powder Recovery:.

Benefits of our Powder Booths

1,Multi-Cyclone recovery system ensures extremely high levels of powder recovery 98% .

2,Faster Color Change:The Bottom of the Booth prevents accumulation of the powder and makes it very easy for cleaning and quick Color change.

3,Higher life of cartridge filter with unique Rotary wing cleaning mechanism

Technical Date:

| Outside size | 4000 x W 1200 x H 3000mm |

| Workpiece opening | W700x H1800mm |

| Touch up opening | W700 X H1500mm |

| Auto gun opening | W 100 x H 1750 mm |

| Exhaust | 8,000 M3/Hr(150mm/Aq) |

| Fan type | Anti-explode Fan |

| Booth Carbin material | SUS304 |

| Fluorescent lamp | 40W |

| Cartridges filter | 10pcs |

| Booth the average wind speed | 0.5M/Sec.(150mm/Aq) |

| Voltage | 380V |

The instruction of the spray booth

Gun Movers

AutomaticReciprocator (reciprocating machine) (Work with Electrostatic PowderCoating Gun) With several

electrostatic powder coating gun on thereciprocator Japan Mitsubishi Transducer

Four automatic spray gun rods(qty of the rods can be ordered)

Colour can be ordered.

The COLO-5000-800D Control system with the 800D automatic powder spray

guns especially designed to meet the requirements of serial production

in powder coating, where reliability in automated operation, easy to

handle operation and security are the most projecting advantages for the user.

The type and the number of installed control units could make as your

requirements.

Powder sieving machine

The system is able to continuously sent the powder being dropped during the

process of spraying to the upper part of the butterfly powder screen and then

the selected powder is sent to the centralized powder supply barrel which is in

charge of continuously supplying powder to automatic guns or manual guns

One of our customers who want to get very perfect recovery effect, he asked me how could get a recovry rate about 99.99%,

COLO mainly research the technique of

the recovery system. We suggest use the

filters and

cyclone.

We make a details design for the customer, including

six automatic powder spray painting guns, two Reciprocators, three guns each reciprocator. over head conveyor, powder paint spray booth, cyclone recovery system, gas fired tunnel oven.

The costomer confirmed our design, and then makeadvance deposit. we finished the produce in about 120days. then the costomer make payment of the balance. After the goods was sent by sea, we went to the customer's place, help them install and testing. The customer afford the

airticket cost and the cost of living in their contry during the time of installing.

Untill now, about half year past, all the equipments work very well, my customer said he will make another

powder coating line later and he will contact me then.

We sincerely hope to provide the best and professional service to our customers, and build long cooperation renation.

If you have enquiry about powder coating paint line, please contact me: I am Monica