|

Hangzhou Color Powder coating Equipment co.,ltd

|

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

car spray painting machine

Designedfor small sample testing or powder manufacturers, the Cup Unitincorporates the application cup to the gun. The cup is self-fluidizingand is easy to clean, making color changes fast and easy.

For the item COLO-500-PGC1 ,The specification as follow:

0-100 Digital Adjustable KV

Fully Adjustable Amperage

Interchangeable with the ITW Gema PGC1 control unit and PG1 gun

Fully Adjustable Air for Pump on Pressure, Dosage and Nozzle Rinsing Air.

Comes with trolley,hopper and Full Array of Nozzle Assortment.

Field Tested and Proven to operate in the toughest environments.

Comes with different array of delivery systems:

Because this system is specially balanced for the maximum spray capability with

the Smoothest Finish Possible.

Canister Feed - CUP

Because this system was designed with the Pulse Power Built in its

Electronics it is specially balanced for the maximum spray capability with

the Smoothest Finish Possible.

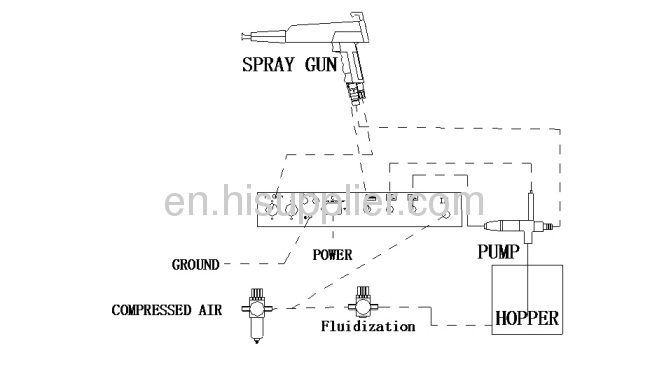

Manual coating equipment Function description

the powder gun through the powder hose . The powder is electrostatically

charged at the nozzle of the gun. In addition, an electrostatic field is

created between the gun nozzle and the grounded object. The charged

powder spray remains adhered to the surface of the object.

The powder is fluidized by air forced through a porous plastic plate from

below. The powder acquires, thereby, fluid-like characteristics.

The conveying air, supplementary air, and rinsing air are set on the control

Unit

Include

A control unit power supply cable

- A air filter

- A fluidized powder hopper

- An manual cup powder gun with gun cable, powder

hose, rinsing air hose and standard nozzle set.

- Pneumatic hoses for conveying air (red), supplementary

air (black) and fluidizing air (black)

Ground wire

AIR BLOW GUN

Electrical data

Mains input voltage: 220V/110V

Operating frequency: 50Hz /60Hz

Powder: 50W

Output voltage (to the gun): 0-100KV ( adjustable)

Maximum output current (to the gun): 180UA(max)

Protection type: IP54

Approvals: CE Certification

Pneumatical data

Input pressure: Min. 6 bar(87PSI)/max. 10 bar(145PSI)

Recommended input pressure: 7 bar(101.5PSI)

Max. Water vapor content of the compressed

Air 1.3 G/m 3;

Max. Oil vapor content of the compressed air 0.1 mg/m3;

Packing Dimensions

Length: 44cm

Width: 44cm

Height: 56cm

Weight: 12 kgs.

Theprocess of the coating is like this :the powder is fluidized in thepowder hopper. The injectors transport the powder through the hoses tothe guns . The guns spray a powder/air mixture onto the workpieces.

Powdercoating is a type of coating that is applied as a free-flowing, drypowder. The main difference between a conventional liquid paint and apowder coating is that the powder coating does not require a solventto keep the binder and filler parts in a liquid suspension form. Thecoating is typically applied electrostatically and is then cured underheat to allow it to flow and form a "skin". The powder may be a thermoplastic or a thermoset polymer.It is usually used to create a hard finish that is tougher thanconventional paint. Powder coating is mainly used for coating of metals, such as "whiteware," aluminium extrusions, and automobile and bicycle parts. Newer technologies allow other materials, such as MDF (medium-density fibreboard), to be powder coated using different methods.

The powder coating process involves three basic steps:

Part preparation or the pre-treatment

The powder application

Curing